Contact Us

Contact: Mr. Li

Phone/WeChat:+8613253218186

Email:Lisa@juqiwiremesh.com

WhatsApp:+86-13315854866

Application scope: Faucet, sink

Application scope: Faucet, sink

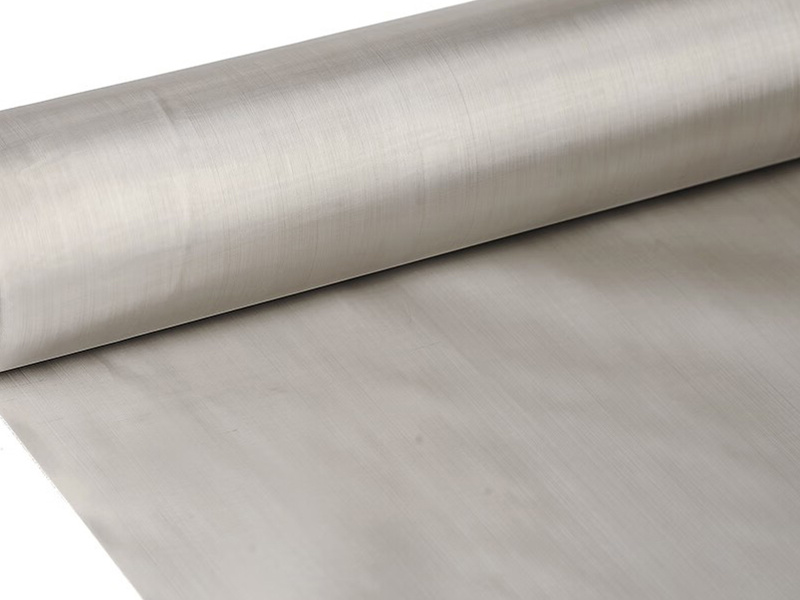

Product Applications: petrochemicals, industrial filtration, etc.

Product Applications: petrochemicals, industrial filtration, etc.

Product Applications: petrochemical industry, industrial filtration, etc.

Product Applications: petrochemical industry, industrial filtration, etc.

From the perspective of user experience, stainless steel filters are characterized by their reusability and ease of cleaning. This reduces the hassle of frequent replacement and lowers long-term usage costs, making them particularly suitable for high-frequency scenarios such as filtering residue in sinks and filtering tea.

From the perspective of user experience, stainless steel filters are characterized by their reusability and ease of cleaning. This reduces the hassle of frequent replacement and lowers long-term usage costs, making them particularly suitable for high-frequency scenarios such as filtering residue in sinks and filtering tea.

The high-temperature resistance and customizable shapes of stainless steel filters are distinct advantages. They can be used in high-temperature environments such as preventing oil splashes in ovens and filtering residue in frying pans. They can also be processed into various shapes like round and square according to needs, precisely fitting different devices such as soy milk machines, air conditioner air outlets, and industrial filters, offering great flexibility.

The high-temperature resistance and customizable shapes of stainless steel filters are distinct advantages. They can be used in high-temperature environments such as preventing oil splashes in ovens and filtering residue in frying pans. They can also be processed into various shapes like round and square according to needs, precisely fitting different devices such as soy milk machines, air conditioner air outlets, and industrial filters, offering great flexibility.

The most prominent features of stainless steel filters are their strong corrosion resistance and food-grade safety. They do not contain harmful substances and will not contaminate food when in direct contact with soy milk, edible oil, etc. They are suitable for daily use in the kitchen to filter residue and also meet the filtering needs related to food and beverage.

The most prominent features of stainless steel filters are their strong corrosion resistance and food-grade safety. They do not contain harmful substances and will not contaminate food when in direct contact with soy milk, edible oil, etc. They are suitable for daily use in the kitchen to filter residue and also meet the filtering needs related to food and beverage.

Appearance gloss filter delicate, translucent, high strength

Appearance gloss filter delicate, translucent, high strength

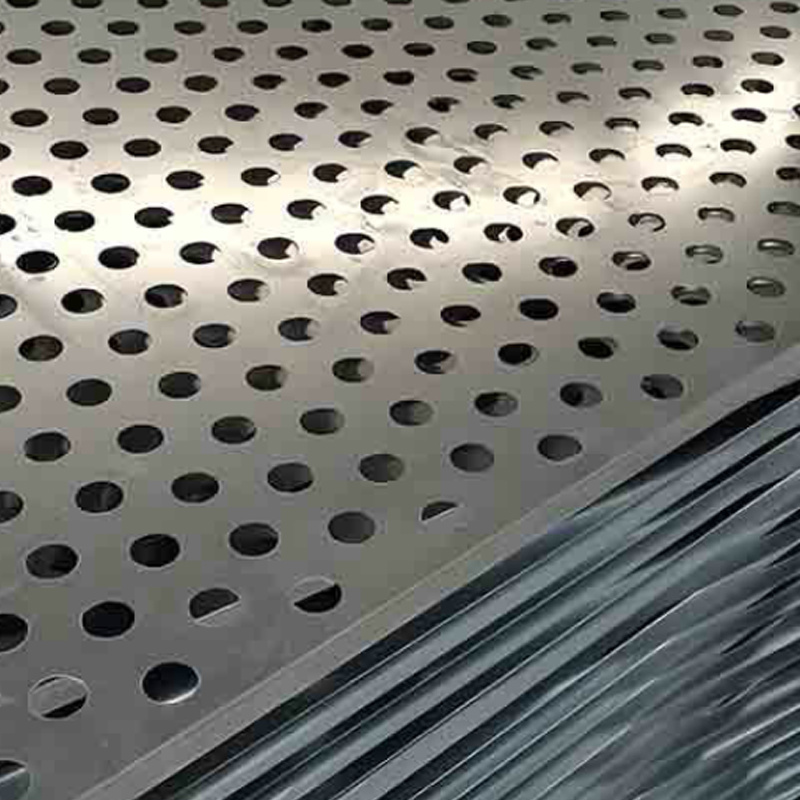

Curtain wall aluminum plate steel mesh

Hole type: Round hole

Mesh width: 6(mm)

Purpose: Applications

Curtain wall aluminum plate steel mesh

Hole type: Round hole

Mesh width: 6(mm)

Purpose: Applications

Perforated aluminum and steel sheets

Hole type: Round hole

Mesh width: 6(mm)

Purpose: Applications

Perforated aluminum and steel sheets

Hole type: Round hole

Mesh width: 6(mm)

Purpose: Applications

Stainless steel metal decorative mesh

Hole type: Round hole

Mesh width: 6(mm)

Purpose: Applications

Stainless steel metal decorative mesh

Hole type: Round hole

Mesh width: 6(mm)

Purpose: Applications

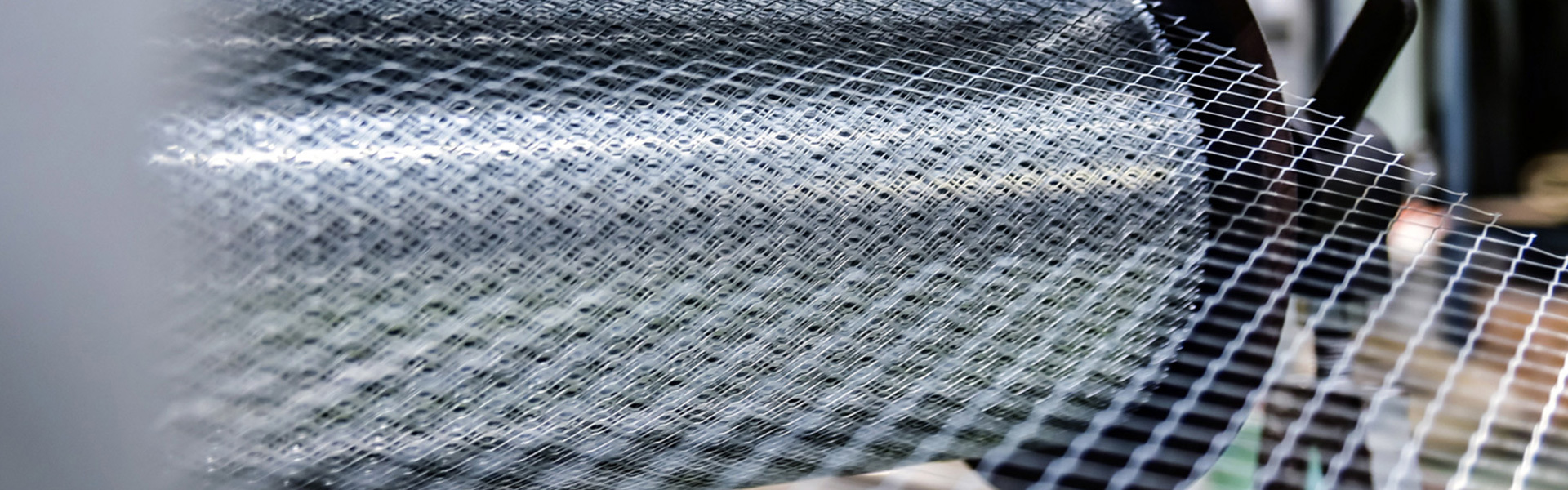

Mining screen mesh is a specialized screening component for mining, made from materials such as high-carbon steel, manganese steel, or stainless steel, processed by weaving, punching, or welding, with mesh shapes mostly square or diamond, and mesh sizes can be customized according to mineral particle sizes (usually 1-100mm). Distinctive features: First, it is wear-resistant and impact-resistant, able to withstand friction and impact from minerals, with a long service life; second, it has high screening efficiency, with uniform mesh holes and不容易堵塞; third, the structure is stable, can be adapted to vibrating screens and other equipment, widely used in mineral grading, coal block screening, tailings separation, and other mining scenarios.

Mining screen mesh is a specialized screening component for mining, made from materials such as high-carbon steel, manganese steel, or stainless steel, processed by weaving, punching, or welding, with mesh shapes mostly square or diamond, and mesh sizes can be customized according to mineral particle sizes (usually 1-100mm). Distinctive features: First, it is wear-resistant and impact-resistant, able to withstand friction and impact from minerals, with a long service life; second, it has high screening efficiency, with uniform mesh holes and不容易堵塞; third, the structure is stable, can be adapted to vibrating screens and other equipment, widely used in mineral grading, coal block screening, tailings separation, and other mining scenarios.